FAQ

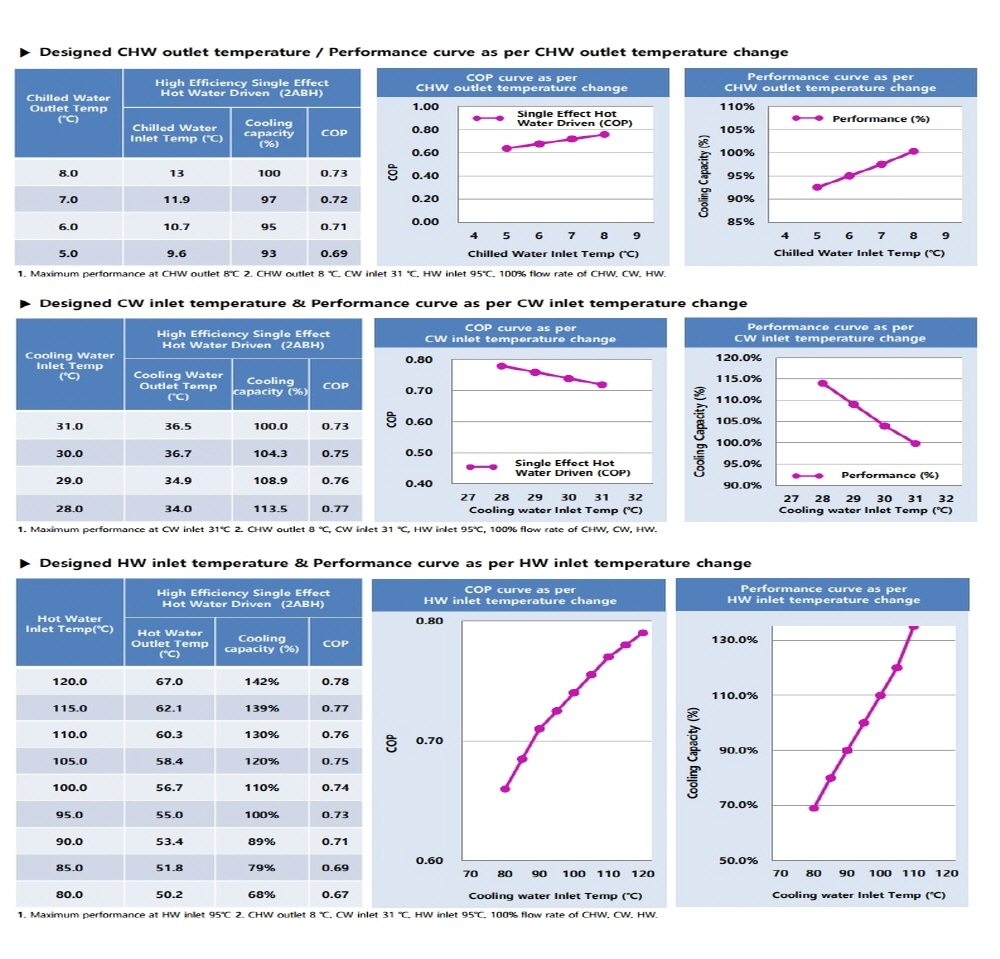

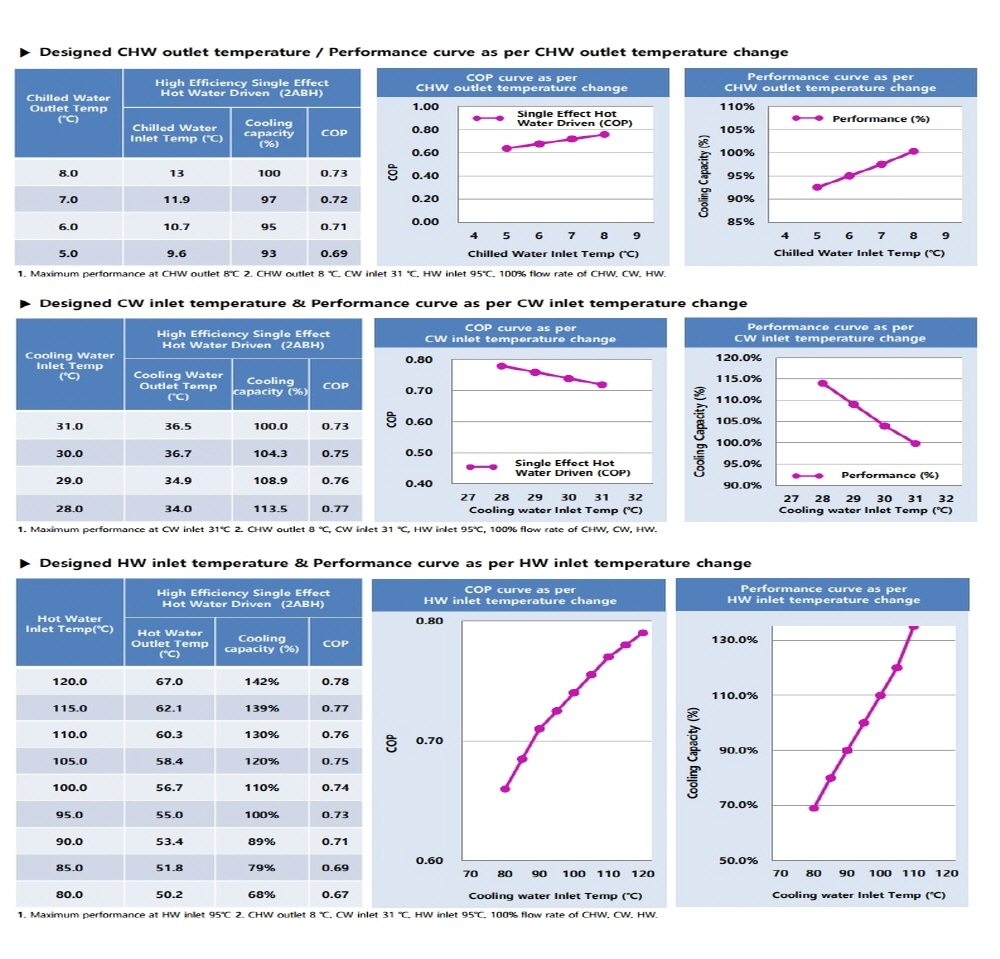

1When the temperature at the exits and entrances of high-efficiency low-temperature water?

stage absorption chiller changes, will the capacity of these devices rapidly decline?

The performance of products of World Energy changes and adapts in accordance with changes in the temperature of cold water, cooling water and hot water and it is generally known that there is no rapid deterioration in performance.

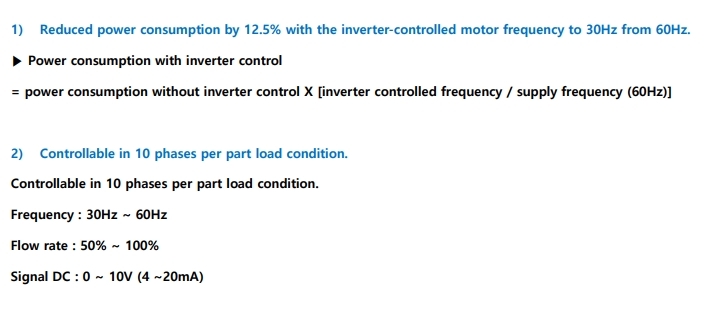

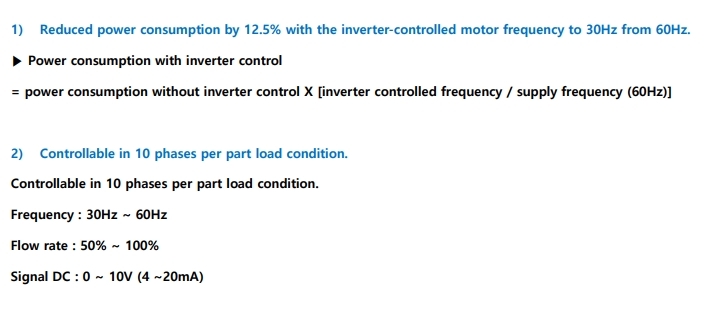

2During low-load operation, are there ways to reduce cold water and cooling water pumping power?

In the case of low-load operation, pumping power can be reduced through applying inverters to cold water pumps and cooling water pumps.

*Installation of cold water and cooling water inverters is the responsibility of consumers and the manufacturer only provides control signals

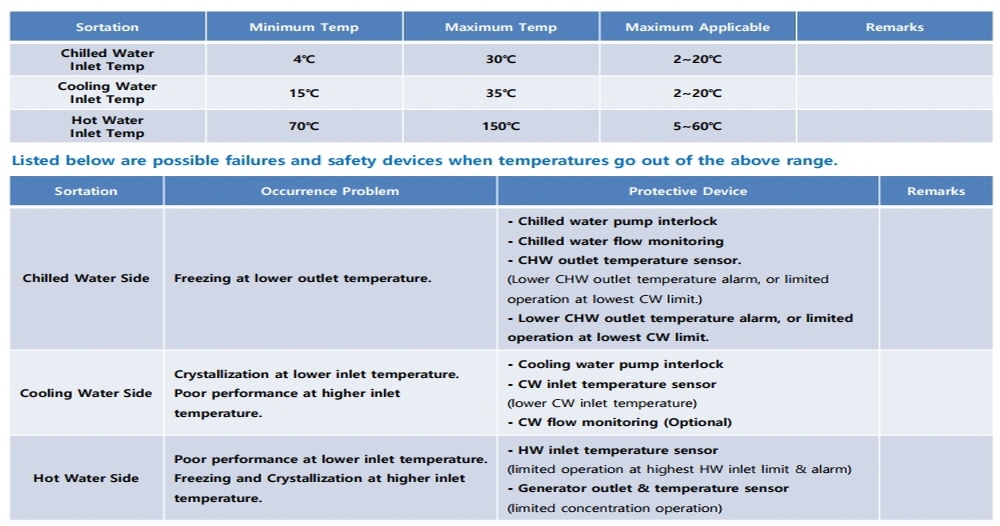

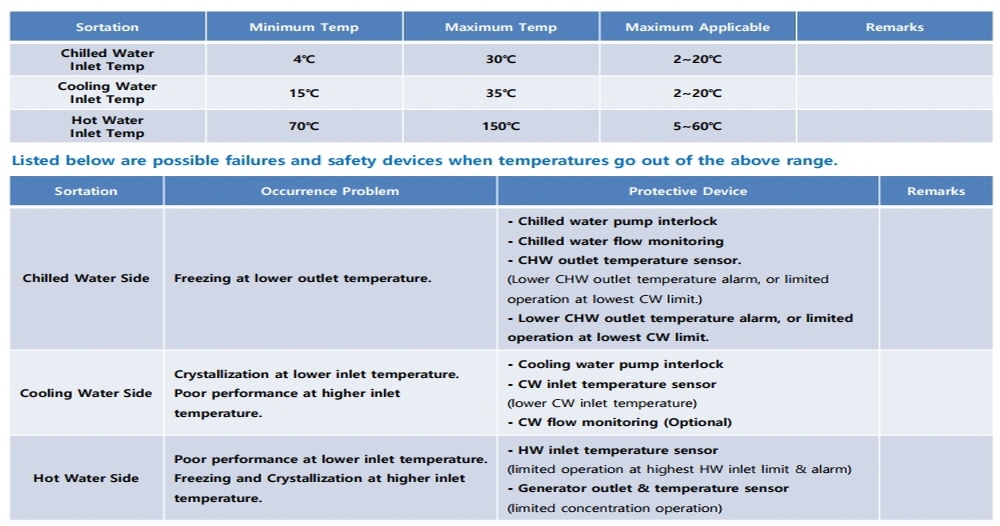

3Regarding high-efficiency low-temperature water 2-stage absorption chiller, what is the applicable temperature at exits and entrances?

World Energy is a global company which develops, produces and sells absorption refrigerators. The range of temperature which is possible at present is as follows.

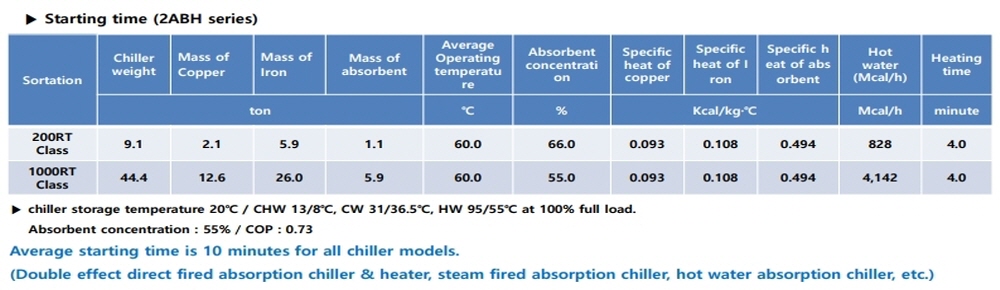

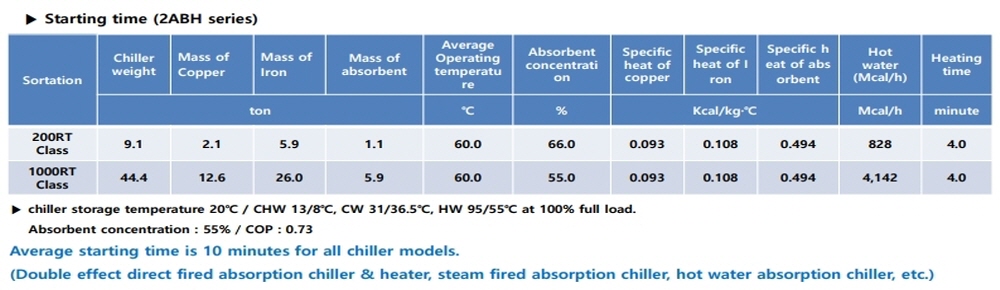

4It is said that absorption chiller need a longer starting time than compression (turbo, screw) chiller. Is this true?

Starting time of absorption chiller is just about 10 minutes considering the time needed to heat absorption liquid and to start control valves. Compression chiller with lubricating devices need about five minutes to start. Taking these aspects into consideration, a starting time gap between absorption chiller and electric chiller is about five minutes.

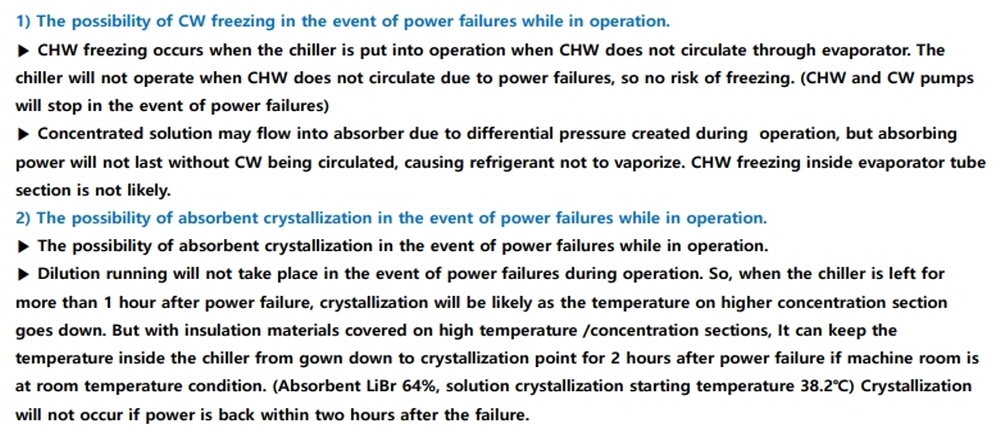

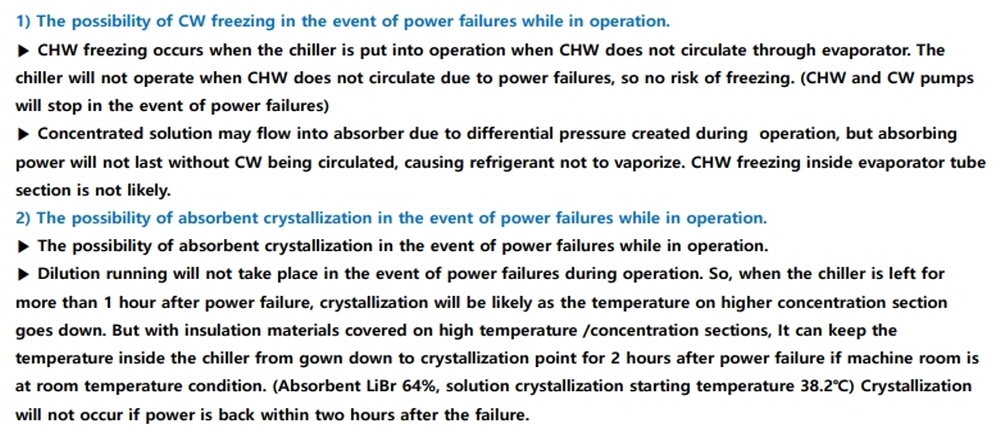

5It is said that emergency power supply is necessary while operating absorption chiller because cold water can freeze and absorption liquid forms crystals during power cuts. Should I have an emergency power system?

You don’t need it.

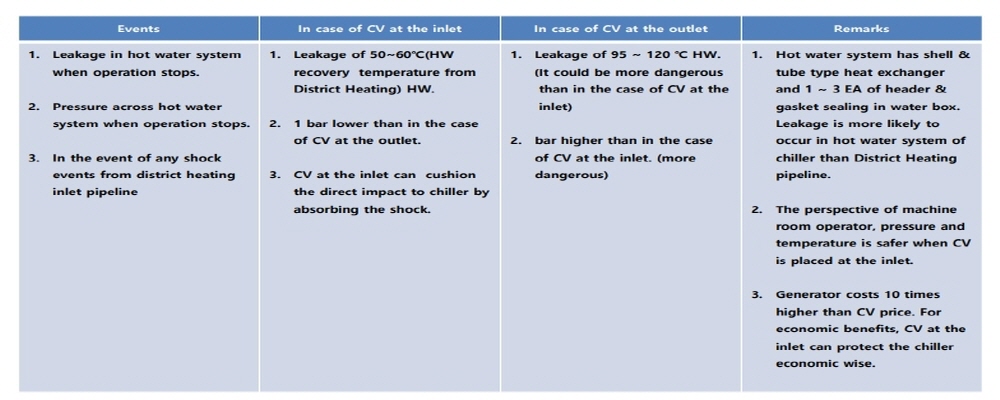

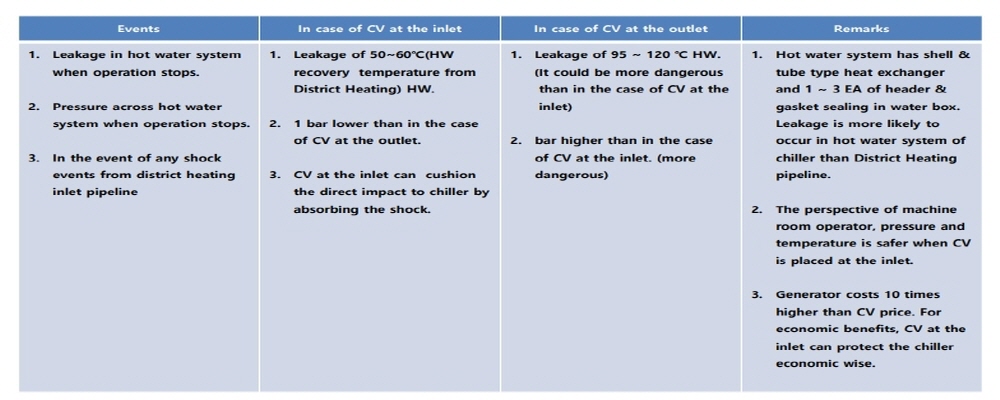

6Where should hot water control valves be installed?

We recommend that valves should be installed around the entrance for the following reasons.