Absorption Chiller Principle

1Evaporation of distilled water (refrigerant) at low temperature and low pressure

Absorption chiller use distilled water as a refrigerant.

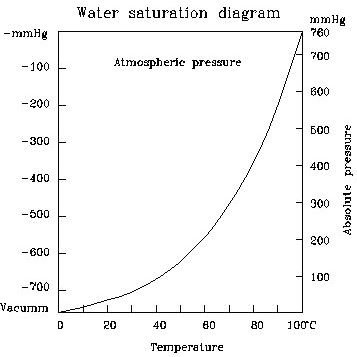

When water is heated to 100℃ in atmospheric pressure, it boils and evaporates.

Evaporation temperature changes as a table on the right depending on pressure conditions. Therefore, the evaporation temperature changes and it can drop to lower than 100℃ when the pressure is lower than atmospheric pressure.

Absorption chiller remove or transfer air inside to the outside, maintain evaporators which directly make cold water in a vacuum of 6~7 (-753)mmHg, and then boil water, a refrigerant, at about 5℃ and evaporate it.

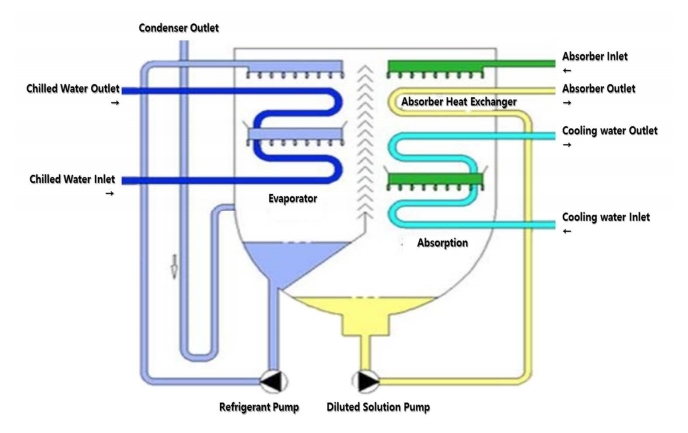

2Evaporation and absorption

Use LiBr aqueous solution as an absorbent.

Remove non-condensable gas from inside the body and maintain pressure of 6.5mmHg.

If water is dropped to a heat tube, water evaporates at 5℃.

When water evaporates, the heat of water inside the heat tubes is extracted and the water whose heat was extracted is used for cooling.

Evaporated steam (a refrigerant) containing heat is absorbed into a LiBr aqueous solution. Such an action needs a vacuum to be continued.

When steam is saturated in LiBr aqueous solution, such an action is not possible.

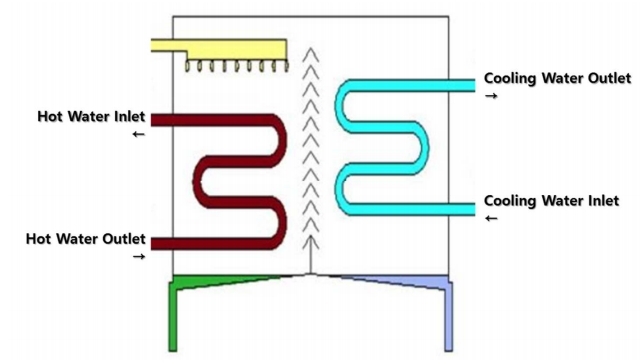

3Regeneration and condensation

A dilute solution absorbing refrigerant steam at an absorber is moved to a chiller.

A dilute solution scattered in the upper part of the chiller is heated with hot water and concentrated. (move to an absorber)

Refrigerant steam makes heat exchange with cooling water to be condensed and moves to an evaporator.

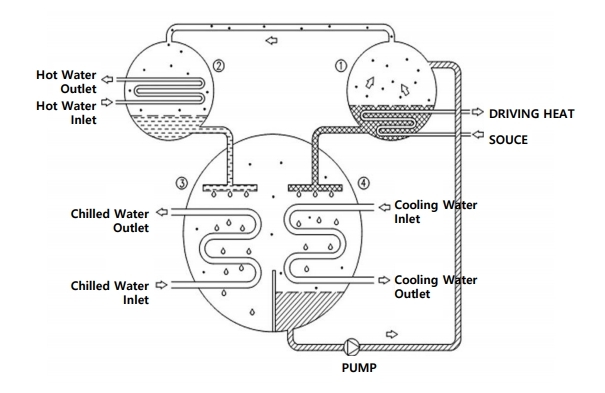

4Basic single-effect absorption cycle

A basic cycle of a low (middle)-temperature hot water absorption Chiller. A name of each part is as follows.

generator, condenser, evaporator, absorber. Cooling water flows through an absorber and a condenser.

Cooling water condenses refrigerant steam generated at a regenerator to make refrigerant liquid and absorbs heat when the absorption liquid of an absorber absorbs refrigerant steam evaporated at an evaporator.

① Heating sources (such as district heating hot water) heat dilute solutions and generate refrigerant steam to become thick solutions.

② Refrigerant steam coming from a chiller is condensed by cooling water.

③ Refrigerant steam coming from a chiller is condensed by cooling water.

④ Evaporated refrigerant steam is absorbed into an absorption liquid coming from a chiller of the surface of absorption tubes, and this absorption liquid gets diluted and moves to the chiller.