Double Lift Brine Absorption Chiller

World Energy Brine Absorption Chiller makes up the weakness of the conventional absorption chillers that their lowest chilled water supply temperature is 4℃.

World Energy Brine Absorption Chiller can provide Brine at the temperature of -7℃.

MAKE UP FOR CONVENTIONAL ABSORPTION CHILLER

Absorption Chillers use demineralized water as refrigerant and lithium bromide solution as absorbent, which make the equipment environmentally friendly and harmless to human body. They also reduce energy consumption by utilizing waste heat to provide cooling. However, because of the fact that absorption chillers use water as their refrigerant, generally the minimum supply chilled water temperature they produce is limited to 4℃. World Energy Brine Absorption Chillers make up this point by providing brine in temperatures below zero. As a result, absorption chillers can be able to provide environmentally friendly solutions in a wider range of fields.EXPAND APPLICATION AREA BY SUPPLYING BRINE OF -7℃

World Energy Brine Absorption Chillers use refrigerant mixed with water and lithium bromide solution, so that they can decrease the evaporative temperature of refrigerant to 0℃ or less. Brine can be supplied at -7℃, which is applicable not only to comfort cooling but also to cold storage and process cooling.AUTOMATIC ABSORBENT CONCENTRATION CONTROL SYSTEM

World Energy Brine Absorption Chillers are equipped with an automatic absorbent control system which keeps the concentration level of lithium bromide in refrigerant at a certain level, even though the cooling load changes from 0 to 100%. It makes the outlet temperature of brine stay stable and prevents refrigerant from freezing.VARIOUS FIELDS OF APPLICATION

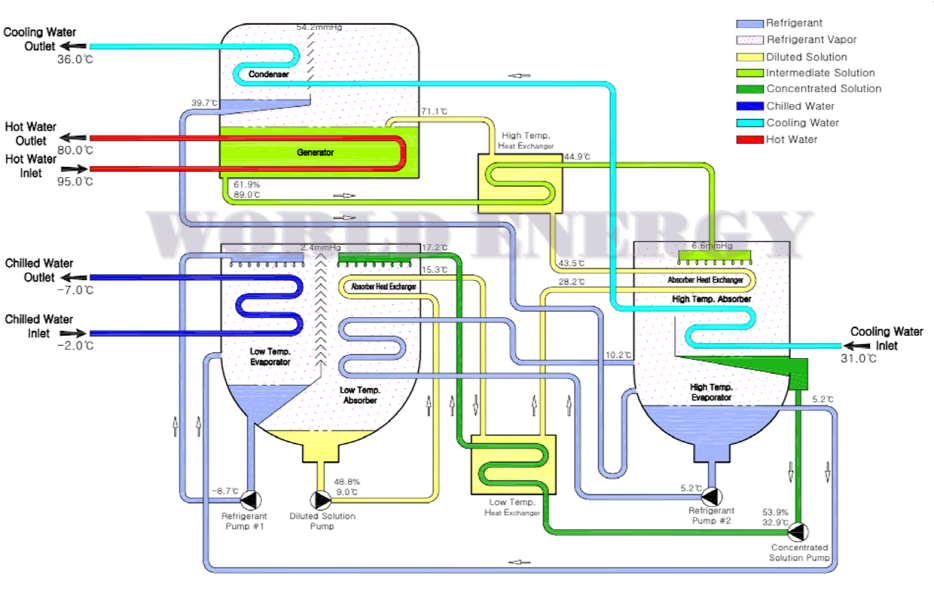

A wide range of heat sources such as hot water, steam, exhaust gas, or fossil fuel (gas & oil) can be utilized to drive World Energy Brine Absorption Chillers. Also, they can be installed on marine vessels or offshore plants where the chillers are continuously exposed to severe vibration and tilting during their operation. In this case they utilize waste heat from vessel engines.Flow of solution in Double Lift Type Brine Absorption Chiller.

Double Lift Type Brine Absorption Chillers use the single effect double lift absorption refrigeration cycle combining two sets of evaporator and absorber, whereby the low temperature heat is pumped in two stages and achieve a large temperature difference. It allows the brine can be supplied at -7℃.

In absorption chillers, heat is pumped by using the saturation temperature difference between the refrigerant (demineralized water) and the absorbent (lithium bromide solution).

Therefore, by increasing the concentration level of absorbent in the absorber, the temperature difference between air temperature and chilled water temperature can be widened. However, there is a limit to the concentration level because it also increases the risk of crystallization.

Moreover, Brine Absorption chillers have little saturation temperature difference between refrigerant and absorbent, as the refrigerant is mixed with lithium bromide.

For that reason, two sets of evaporator and absorber are installed in order to provide brine of -7℃. The COP is approximately 0.4.

In absorption chillers, heat is pumped by using the saturation temperature difference between the refrigerant (demineralized water) and the absorbent (lithium bromide solution).

Therefore, by increasing the concentration level of absorbent in the absorber, the temperature difference between air temperature and chilled water temperature can be widened. However, there is a limit to the concentration level because it also increases the risk of crystallization.

Moreover, Brine Absorption chillers have little saturation temperature difference between refrigerant and absorbent, as the refrigerant is mixed with lithium bromide.

For that reason, two sets of evaporator and absorber are installed in order to provide brine of -7℃. The COP is approximately 0.4.