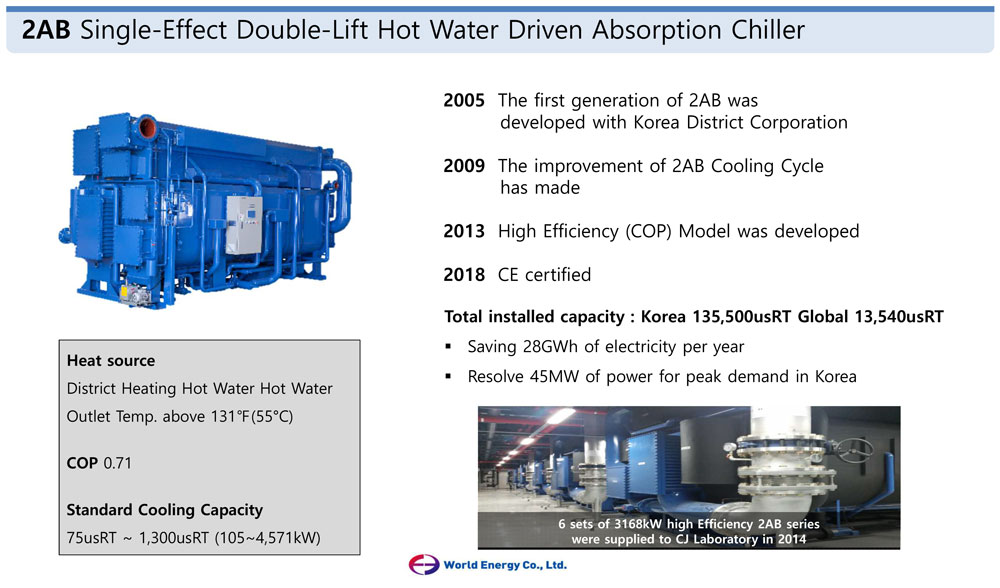

2AB

Single Effect Double Lift Hot Water Driven Absorption Chiller for district heating & industrial use

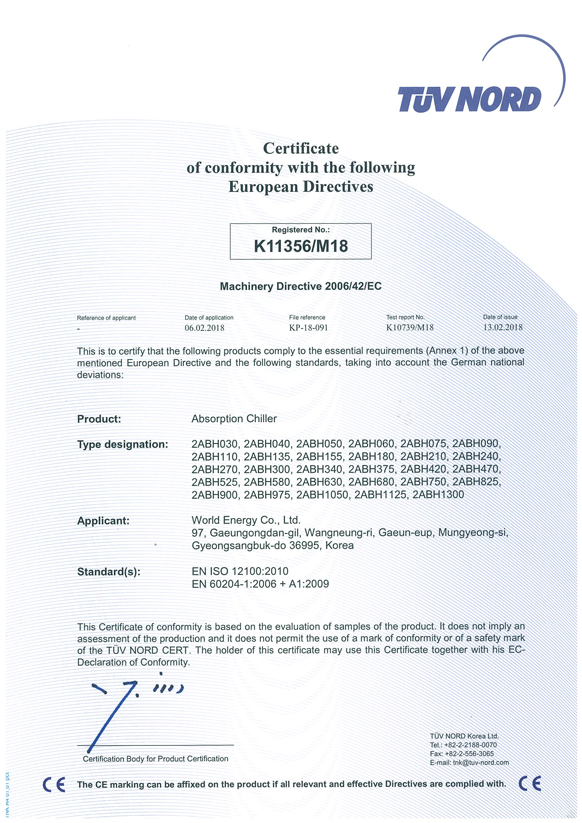

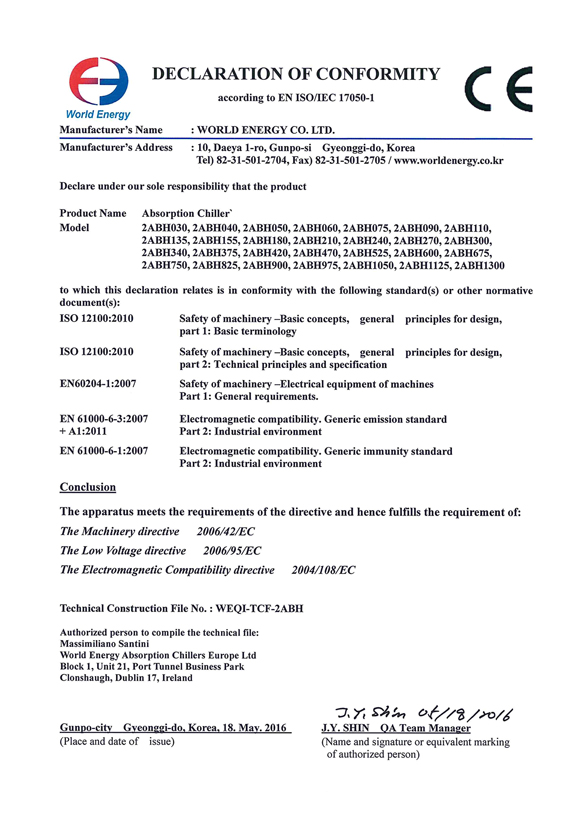

2AB Single Effect Double Lift Hot Water Absorption Chiller

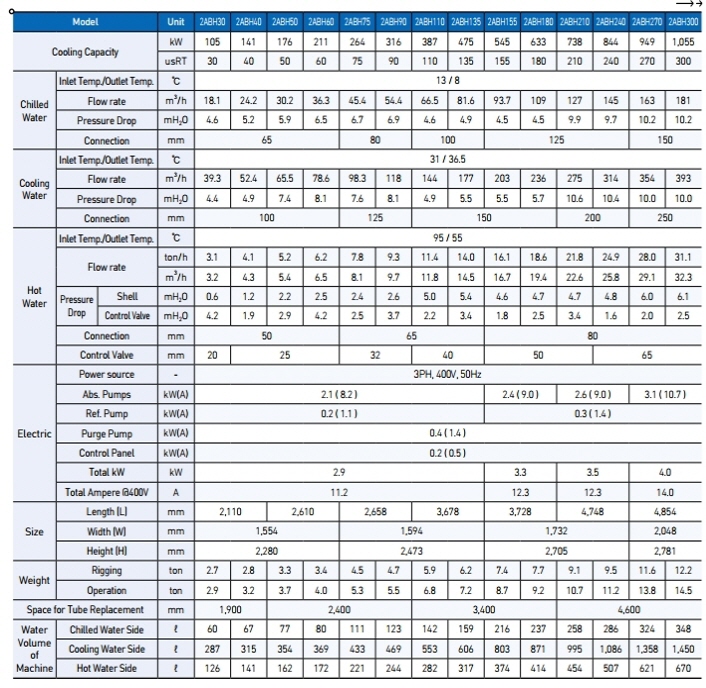

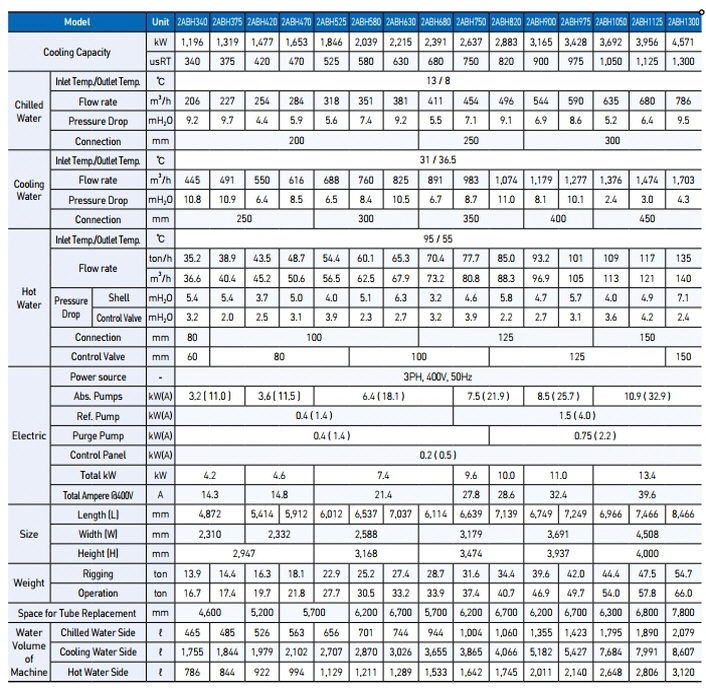

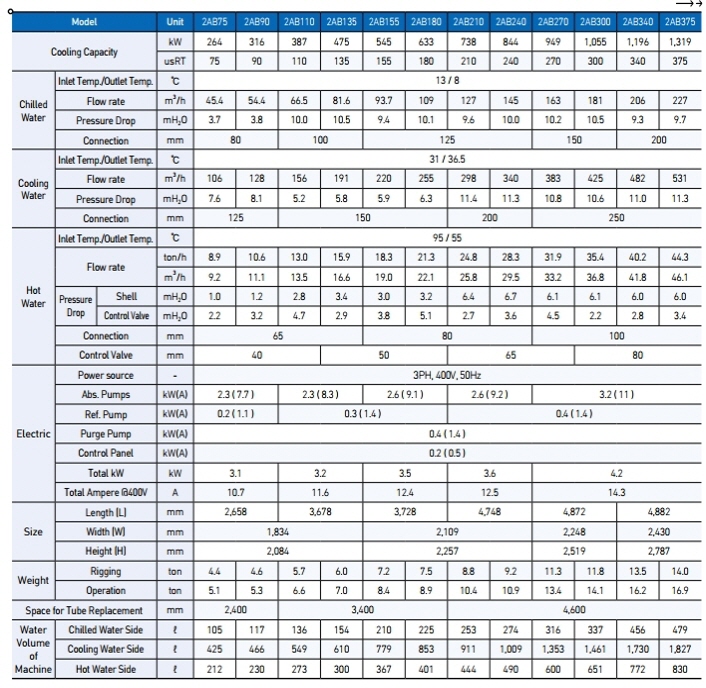

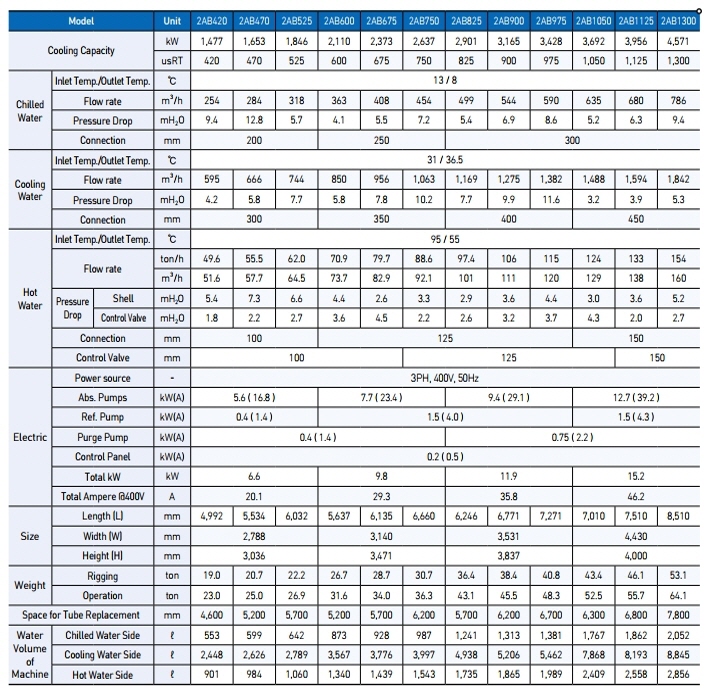

30~2,000RT (105~7,033kW)

Driving Temperature: 80~120℃

Technical standard of district cooling absorption chiller

The first technical standard developed with largest market share in Korean district cooling absorption chillers

Achieved higher than 40℃ delta T and 55℃ leaving temperature of hot water

Combined designs of the single effect type and the double Lift type allows the high delta T and low leaving temperature down to 55℃

Highest COP

Achieved COP 0.73, even with double lift refrigeration cycle

Reference

Korea Incheon International Airport

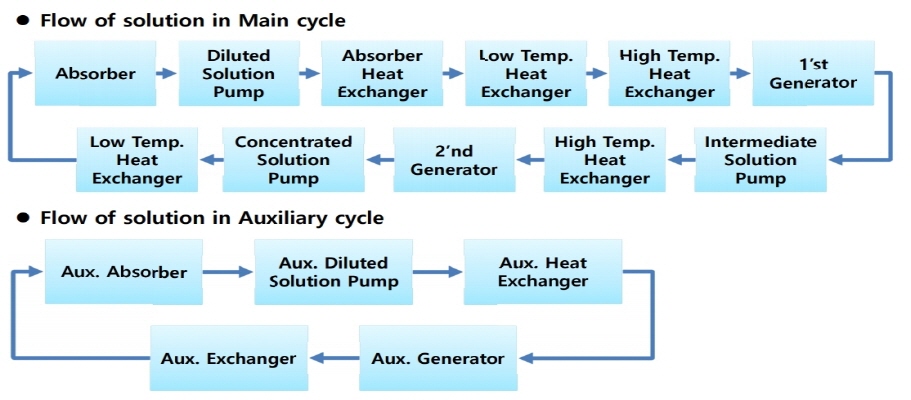

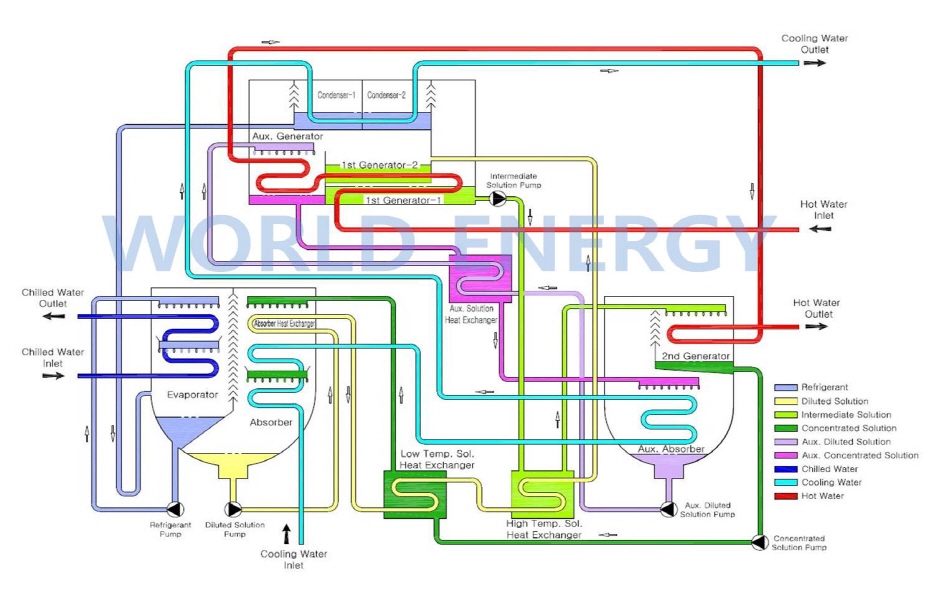

Flow of solution in Single Effect Double Lift Hot Water Driven Absorption Chiller.

Refrigerants evaporate from an evaporator and cool cold water flowing inside of evaporator tubes. Refrigerants evaporated at this time go to an absorber and get absorbed into a thick absorption liquid (a concentrated solution) flowing down from a generator.

Thick absorption liquid (a concentrated solution) from a generator and weak absorption liquid (a dilute solution) from an absorber exchange heat at an absorption heat exchanger located at the upper part of the absorber to improve absorption power of the concentrated solution and enhance the efficiency of the Chillers.

The concentrated solution coming through the absorption heat exchanger absorbs refrigerant steam and becomes a weak absorption liquid (a dilute solution). Absorption heat generated at this time is conveyed to cooling water.

Absorption liquid (a dilute solution) diluted at an absorber goes to a generator through an absorption heat exchanger and a heat exchanger. Hot water of 95℃ heats this dilute solution and generates refrigerant steam.

The dilute solution becomes a thick absorption liquid (a concentrated solution) at the regenerator and returns to the absorber through the heat exchanger.

Refrigerant steam generated from the generator gets condensed outside of condenser tubes and flows down to the evaporator. Cooling water absorbs heat generated when refrigerant gas gets condensed at condenser tubes.

The refrigerant vapor generated in the first generator and the auxiliary regenerator is condensed outside the condenser heat transfer pipe and descends to the evaporator, and the cooling water absorbs the heat radiated as the refrigerant gas condenses in the condenser heat transfer pipe.

The flow of the hot water flows in the order of the first generator, the auxiliary generator and the second generator, and the cooling water flows in the order of the absorber, the secondary absorber, and the condenser to form the chiller cycle.

The high-efficiency cold water two-stage absorption chiller consists of two main cycles and two auxiliary cycles, and the solution flow is as follows.

Flow of solution in high-efficiency low-temperature water absorption chillers.