Combined type

Combined type

Combined type basic

Minimize installation area,

High-efficiency operation

Function to minimize installation area

High-efficiency operation guaranteeing economic operation costs

Possible various combinations through section-unit designing

Frame assembling using aluminum mold bars

Easy disjointing and assembling and reduce carry-in and installation costs

Perfect confidentiality using specially structured packing

Structure which can be conveniently maintained and repaired using large access doors

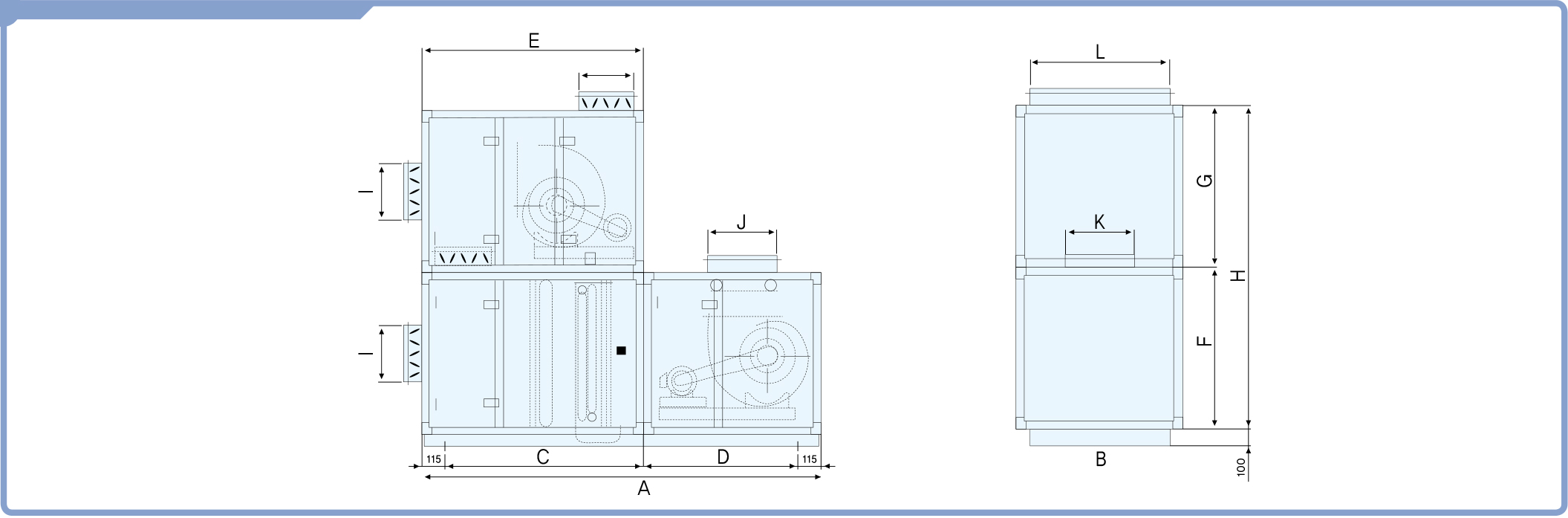

Size of outer appearance – Combined type

CORNER JOINT

As die casting with corner joint aluminum and then sanding was performed, the outer appearance is beautiful. An insulating material made with EPDM was attached to the inner corners. This product is structured to be easily assembled and disassembled.

PROFILE

aluminum was compressed to make the products light and strong, so they work as frames and fix panels. When it is hot and humid like during the rainy season, insulation materials made with EPDM can be attached to the inner sides of the profile to prevent heat transfer.

MEDIUM PROFILE

Located between medium profile panels, they strengthen and fix panels. Insulation materials made with polyethylene are attached to the inner sides of the profile to prevent heat transfer.

MINI PLEAT-type MED.FILTER

Filters are thin and result in little pressure loss. Attached dust isn’t scattered again. Performance is maintained in an even and steady manner through spouting a ribbon material, polyvinyl chloride resin, to maintain fixed intervals.

COIL

Coils with 1/2" copper pipes are applied to coil air volume 560cmm and coils with 5/8" copper pipes are applied for coils with larger air volumes. The SINE WIVE-shaped fins are made to minimize resistance to air flow and maximize surface area.