Automatic Tube Cleaning System

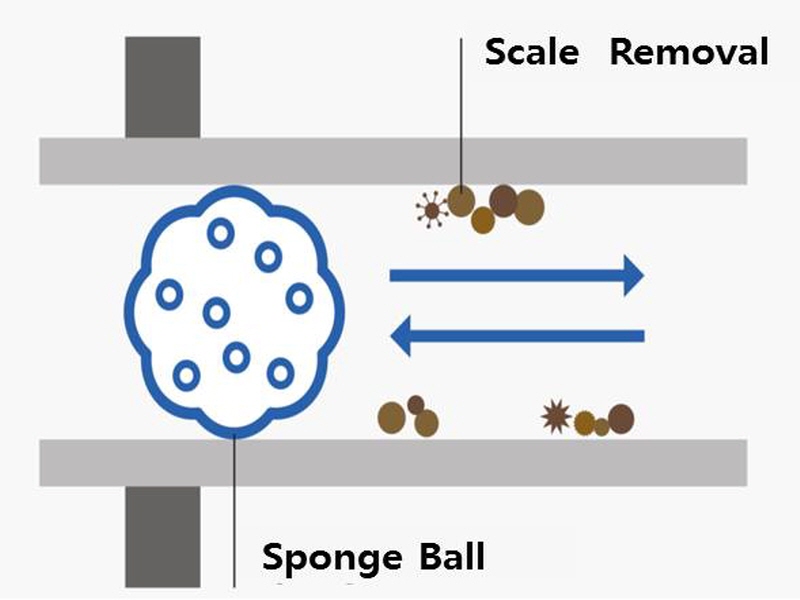

The heat-transfer tubes are managed with regular automatic cleaning for operating in the best condition.

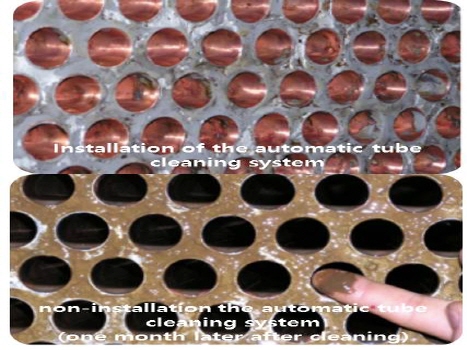

The scale and contaminants attached to the inner wall of the heat-transfer tubes of the cooling water side hinder the heat exchanging, fall the chiller performance and become narrow tube inside not to pass the flow rate well. If you do not clean heat-transfer tubes, a lot of efficiency is wasted, the life-time of the chiller is reduced for this reason regular internal tube cleaning is required. (Recommended once / year)

World Energy’s automatic tube cleaning system manages heat-transfer tubes with regular automatic cleaning; so that the chiller can be operated in optimal condition, resulting in reduced electric energy due to the increased efficiency. Eventually it can save the operating costs, also increase economic feasibility by reducing cleaning cost and management point.Effect of installing automatic tube cleaning system

No necessary maintenance as the all-in-one composition.

Reduced regular cleaning cost and management point.

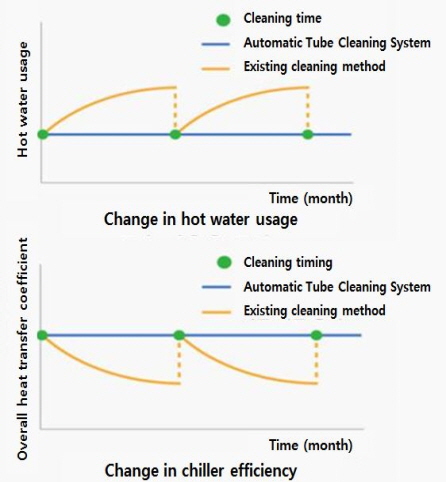

Reduced energy consumption and cost due to the increased efficiency (about 10% energy saving)

Extension of chiller replacement period by extending the life-time of the chiller.

Environmental pollution prevention

Shut-down prevention

Keep the chiller efficiency constantly

Tube cleaning method in the past required heat-transfer tube cleaning because heat efficiency reduced due to the contamination of heat-transfer tubes as time passes. However, this automatic tube cleaning system maintains the efficiency of the chiller constantly through regular automatic cleaning.

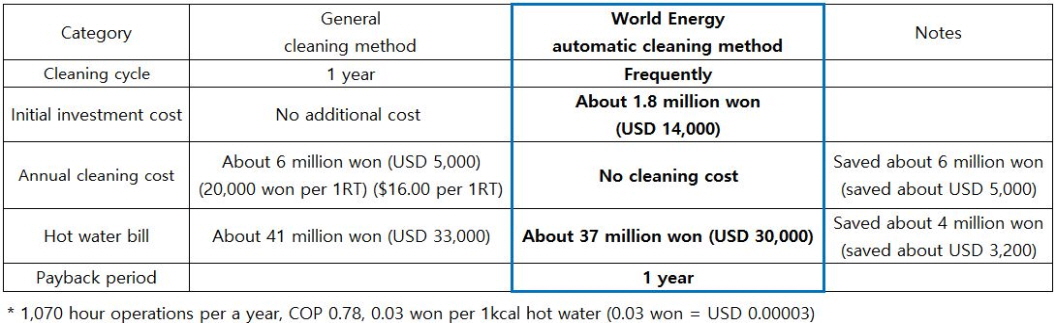

Comparison table of economic feasibility between general cleaning and automatic cleaning method by World Energy (based on 300usRT)