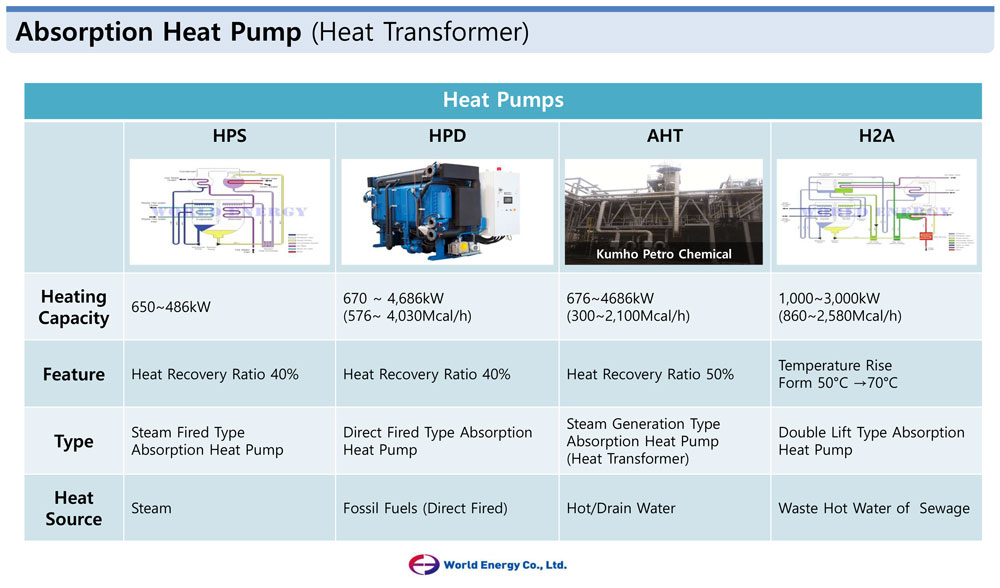

H2A

Double Lift Absorption Heat Pump

Supply hot water through retrieving unused low-temperature waste heat

2-stage absorption heat pumps are devices which can recover heat from unused low-temperature energy, such as wastewater-treating water, and heat and supply hot water. These devices are used when there is a temperature gap between low-temperature heat sources to be recovered and hot water whose temperature is low and which requires a large increase. The only existing technology in this field are 2-stage vapor compression heat pumps which consume a large amount of energy to recover heat from low-temperature wastewater-treating water. Moreover, there are limitations in recovering low-temperature heat with absorption heat pumps which need almost no power. (1-stage absorption uses low-temperature heat sources higher than 30 ℃) When the operation temperature is high, 2-stage absorption heat pumps can improve the COP through producing double effects together. Achieved 20℃ increase in temperature of hot water / Raised temperature of hot water from 50℃ to 70℃ through recovering waste heat from wastewater-treating water heat sources Achieved 55℃ temperature gap in waste heat recovery / Achieved hot water supply temperature of 70℃ through recovering 15℃ wastewater-treating water2-stage absorption heat pump cycle configuration

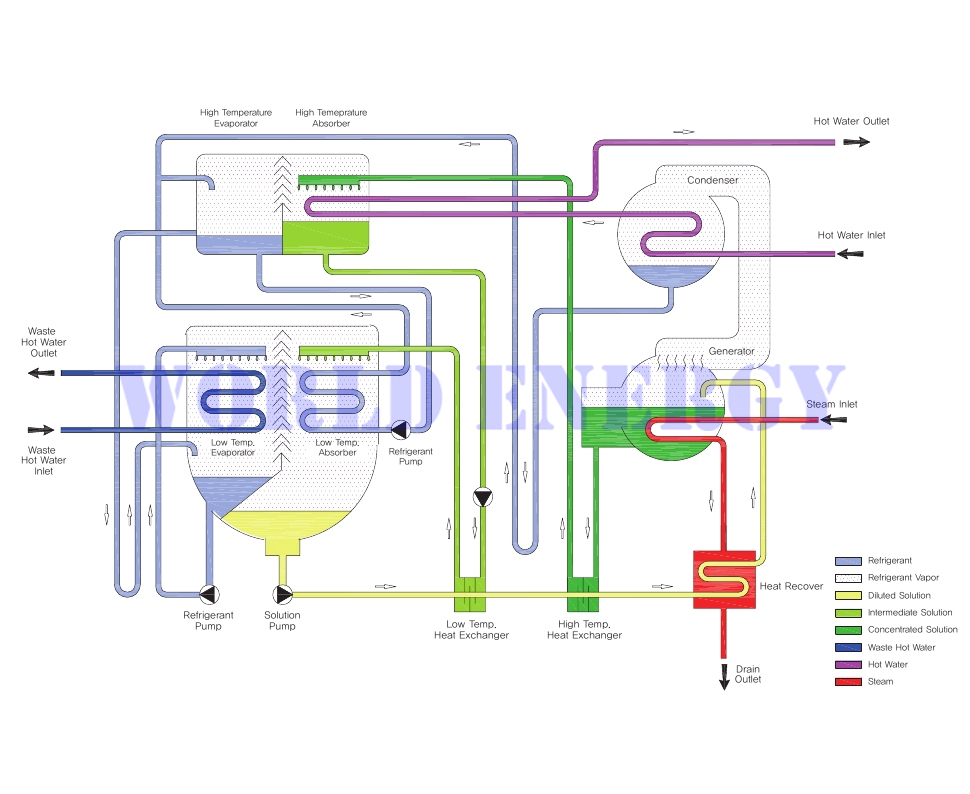

Low-temperature water heat sources flow inside heat tubes of low-temperature evaporators and liquid refrigerants flowing outside of those tubes are evaporated by accepting the waste heat of those low-temperature hot water heat sources. The evaporated refrigerant gas which goes to a low-temperature absorber to be absorbed into an absorption liquid flowing outside of the tubes heats liquid refrigerants of a high-temperature evaporator flowing inside the tubes of a low-temperature absorber.

Those liquid refrigerants go to a high-temperature evaporator to be evaporated. Refrigerant steam evaporated from the high-temperature evaporator goes to a high-temperature absorber to be absorbed into an absorption liquid flowing outside of the heat tubes installed to produce hot water and heat hot water warmed at a condenser to a final temperature. The absorption liquid flowing outside of those tubes is a thick absorption liquid coming from a generator.

A generator applies heat from outside (incineration heat, combustion heat and steam heat can be used as drive heat sources), concentrates the dilute absorption liquid (absorption liquid weakened after absorbing refrigerant steam at an absorber) coming from an absorber and generates refrigerant steam. The amount of refrigerant steam generated at this time is about twice as much as that evaporated at low- and high-temperature evaporators.

Refrigerant steam produced at the generator is condensed outside the heat tubes of a condenser and goes to a high-temperature evaporator, and then principally heats hot water flowing inside condenser tubes.

A part of the condensed refrigerant liquid coming down from a condenser to a high-temperature evaporator is heated at a low-temperature evaporator to be absorbed at a high-temperature absorber. The remaining liquid refrigerants go down to a low-temperature evaporator to be evaporated after absorbing the waste heat of low-temperature hot water heat sources. Low- and high-temperature solution heat exchangers are used for each absorption liquid line.