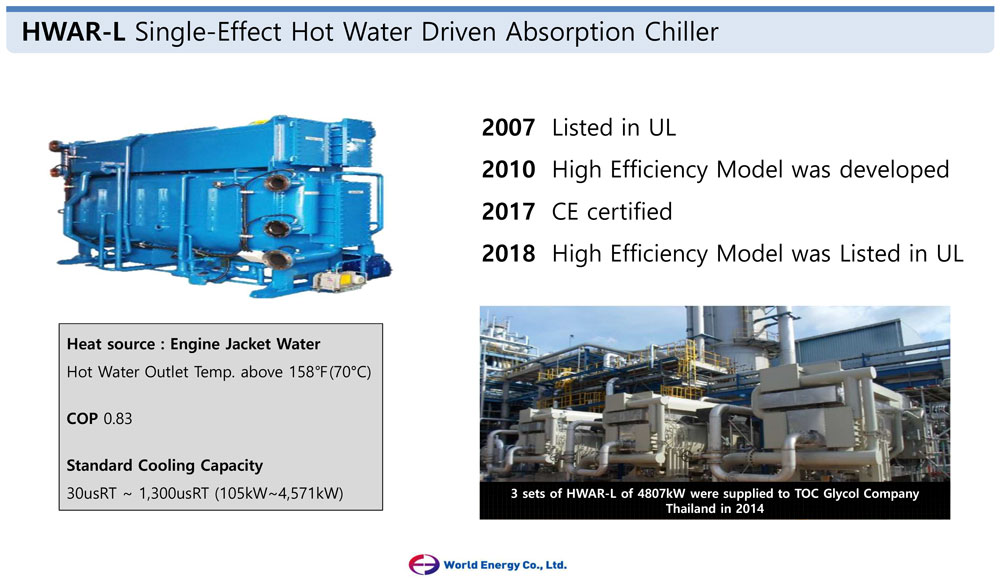

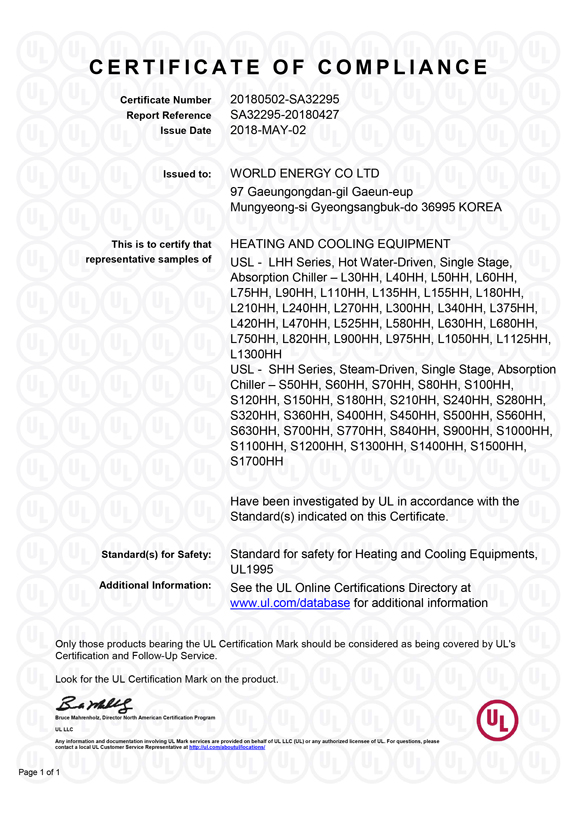

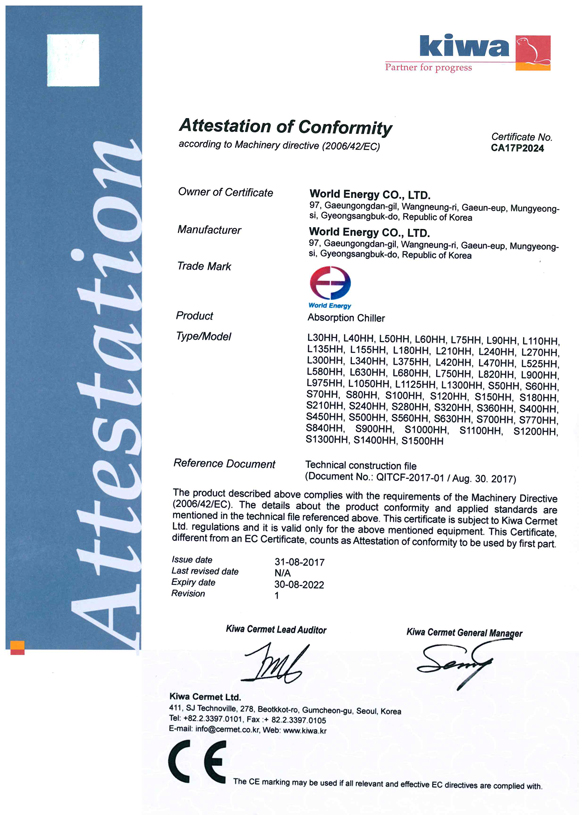

HWAR-L

Single Effect Low-temperature Hot Water Driven Absorption Chiller for cogeneration and industrial use

HWAR-L Single Effect Hot Water Absorption Chiller

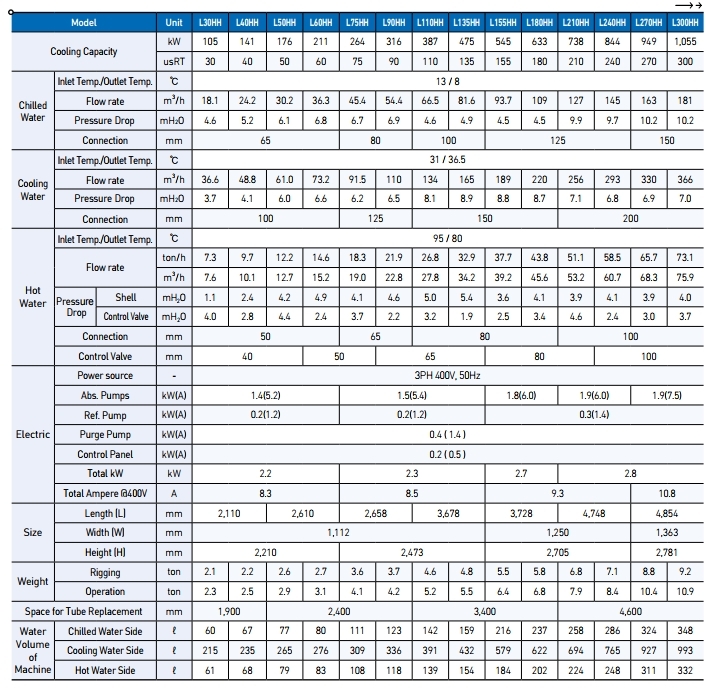

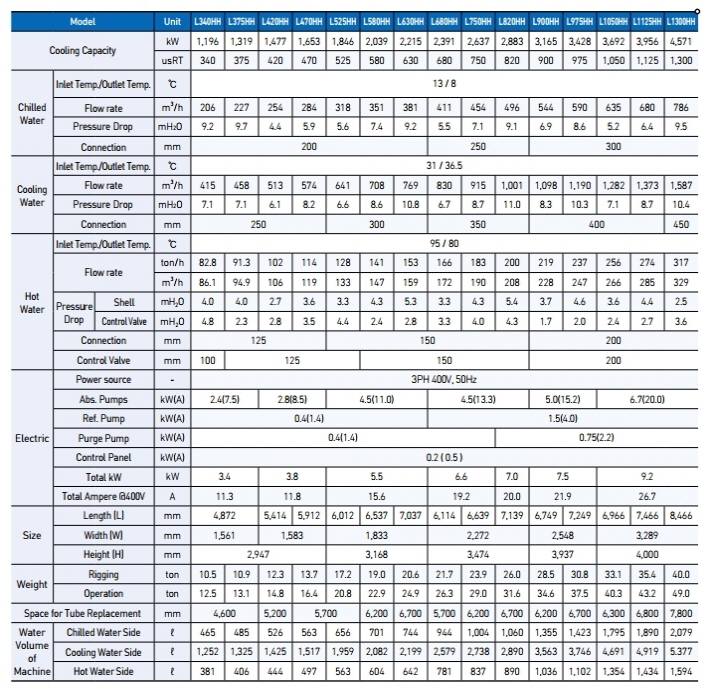

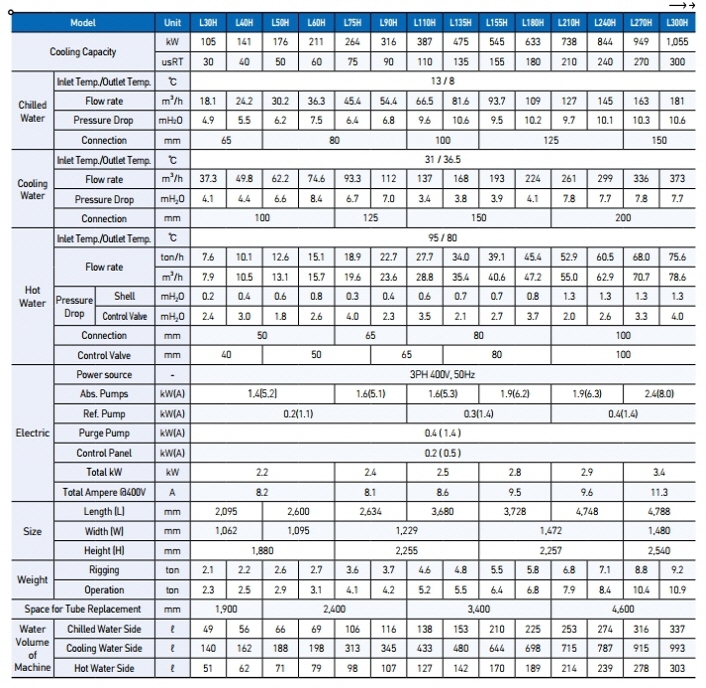

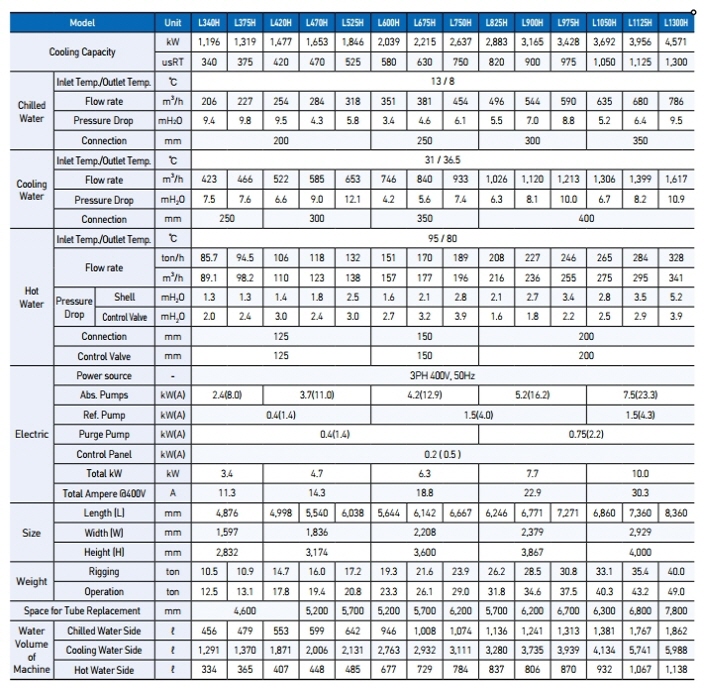

30~2,000RT (105~7,033kW)

Driving Temperature: 80~120℃

Highest delta T in hot water

Achieved leaving temperature of hot water down to 70℃, by the unique 2-shell structured condenser and generator

Lowest power consumption and footprint

Reduced absorbent solution flow rate by the unique 2-level structured evaporator and absorber. Less solution flow rate minimized the power consumption of the solution pumps as well as the size of machine. 60% lesser in power consumption, and 20% smaller in dimension compared to the products of other companies.

Highest COP

Achieved COP 0.825, the highest in single effect hot water driven absorption chillers

Application versatility

Designed to suit a variety of applications, from comfort cooling to providing chilled water for process applications, HWAR-L offers versatility for almost any job where hot water is available as the heat source. HWAR-L is sure to be the right choice for either new construction or retrofit applications.

Excellent part load performance

The standard concentration control system allows stable part load operation at cooling water temperatures as low as 17℃ without the need for a cooling water bypass. For maximum efficiency, a variable frequency drive pump (option) automatically maintains optimum solution flow between generator and absorber at all operating condition. This will result in improved part-load efficiency. HWAR-L has a continuous operating range from 100% to 10% of rated machine capacity.

Reference

Australia Qantas (Sydney Airport), Thailand GC Glycol, USA Macy’s (New York), Millennium Hilton Hotel, CBS Television City, Aquarium of the pacific, Netherland University of Amsterdam

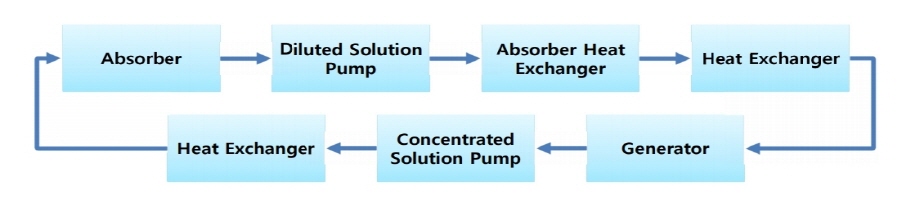

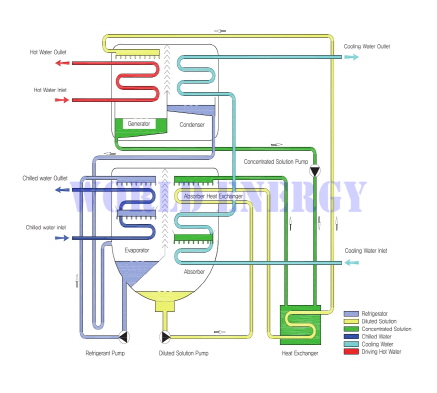

Flow of solution in Single Effect Low-temperature Hot Water Driven Absorption Chillers

Flow of solution in high-efficiency low-temperature water absorption